Bombas Boyser SL and North Ridge Pumps worked closely with a manufacturer of water treatment systems to quickly provide two flocculant dosing pumps for one of their mobile treatment units.

A mine in Australia was in urgent need of a method of treating borehole water for reuse as currently fresh water was being consumed in the mine which was taken from the local towns reservoir, which was now severely depleted with only 3% capacity remaining. This was endangering the towns water supply and its inhabitants meaning urgent action needed undertaking to ensure supply remained intact, and the mine remained operational.

Mine Water Treatment

The borehole water was currently having to be disposed of via tankers due to its high salinity and presence of suspended solids which was sometimes up to 95%. The system needed to extract the water, process it to remove solid content and enable water to be recycled for use in the mine.

The new installation involved fitting a Dissolved Air Flotation (DAF) system where a flocculant is added to the borehole water, meaning solids congregate and float to the surface for ease of separation. However, the DAF is not able to remove all solids, so a secondary filtration system is required to ensure the water is as clean as possible.

The required pumps are positioned between the DAF and the secondary filter and used for dosing flocculant. Centrifugal pumps have a high rotational operating speed and therefore easily damage shear sensitive liquids, the customer explained at enquiry stage that the two pumps must be positive displacement pump type and have a gentle pumping action to avoid damaging the flocculant during transfer and ensure it performs its duty properly.

Application details

Flocculant dosing, 76m3/h, 4 bar.

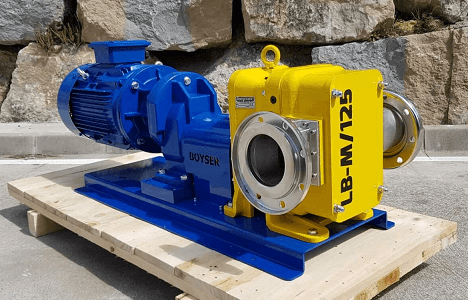

To function correctly, the water treatment system requires each pump to produce a flow rate of 70 to 80m³/hr and a pressure of 4 bar. This not only ensures it functions but also guarantees that the filters are cleaned and do not clog. After reviewing all the information provided, 2 Boyser LB-M/125 horizontal Rotary lobe pumps complete with gear box and 22Kw motors were selected. This model produces 76m³/hr at 4 bar with the gearbox reducing the operating speed to 428RPM. The design of the lobes and the slow rotational speed creates a gentle pumping action that protects shear sensitive fluids during transfer.

Why use a Rotary Lobe Pump?

Lobe pumps are excellent for a wide range of applications involving both high and low viscosity fluids. Large solids can also be handled without incurring damage, they are particularly favoured in the food industry for handling grapes and olives.

The smooth and gentle rotation of the lobes additionally creates minimal pulsations, a common problem with other positive displacement pump types. The added ability to self-prime and reversibility of flow provides flexibility for the customer should the installation change or the pumps be moved to a different process in the future.

Larger pumps in the LB-M range can produce flow rates up to 120m³/hr, pressures up to 8 bar and can allow the passage of solids up to 50mm in diameter. The variety of sealing options means these pumps can be customized according customers needs.

Maintenance and cleaning are simple due to a removable front plate allowing easy access to the internal components and mechanical seal. The ability to install heavy duty cartridge mechanical seals and replaceable internal wear plates means abrasive and aggressive fluids can be handled without concern of the complete pump wearing prematurely. The sacrificial plate wears first to protect other components such as the pump casing, the plate is then replaced, and this is far more cost effective.

To provide further flexibility for the engineers on site, the motor installed is suitable for operation by frequency inverter and fitted with PTC sensors for protection. This allows the customer to control the motor speed and therefore reduce or increase the flow rate as required.